Solvent Filter: Your Ultimate Guide To Precision And Efficiency

When it comes to solvent filtration, precision matters. Whether you're working in a laboratory, manufacturing facility, or any other industry that demands clean and pure solvents, solvent filters play a critical role in ensuring quality and safety. These tiny yet powerful tools help remove impurities, contaminants, and particles that could otherwise compromise your processes. But what exactly are solvent filters, and why do they matter so much?

Solvent filtration might sound technical, but trust me, it's simpler than you think. Imagine this: you're brewing your favorite coffee, and you want it smooth, free of grit, and perfect for that morning pick-me-up. Now apply that same idea to solvents used in industries—except the stakes are much higher. Impurities in solvents can ruin experiments, damage equipment, or even pose health risks. That's where solvent filters come in, acting like a superhero for your liquids.

As we dive deeper into this topic, you'll discover everything you need to know about solvent filters, from their types and applications to tips for choosing the right one for your needs. So grab your favorite drink, get comfy, and let's explore the fascinating world of solvent filtration together. Who knows? By the end of this article, you might just become a filtration pro!

- Why Vegamovies Netflix India Is The Next Big Thing In Streaming

- Deephotlinkcom The Ultimate Guide To Unlocking Its Potential

What Exactly is a Solvent Filter?

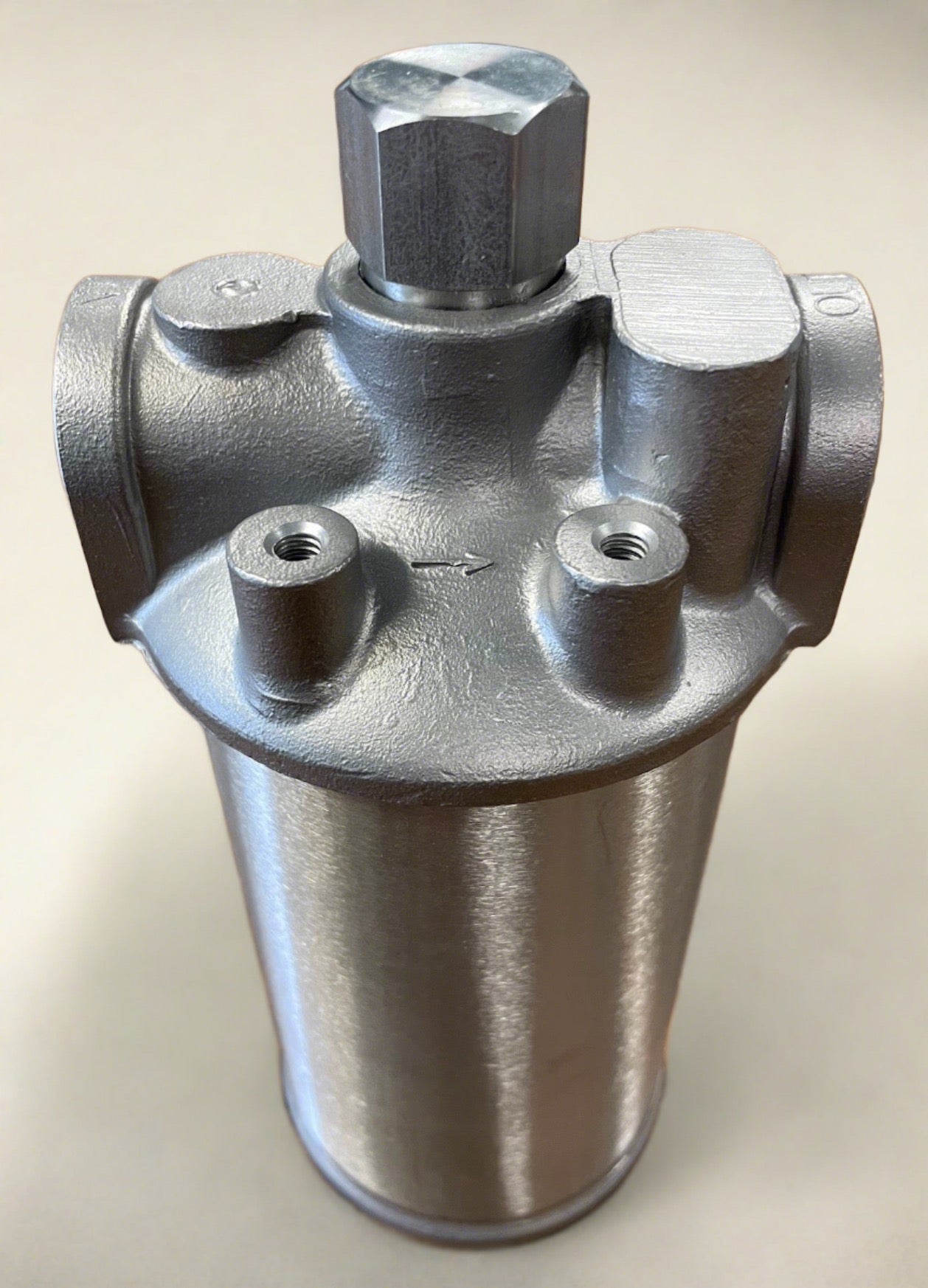

Let's break it down. A solvent filter is essentially a device or material designed to separate unwanted particles, contaminants, or impurities from solvents. Think of it as a sieve for liquids, but way more advanced. These filters come in various forms and sizes, each tailored to specific applications and industries.

Now, here's the kicker: solvent filters aren't just about removing dirt. They ensure that the solvent remains pure, which is crucial for processes like chemical synthesis, pharmaceutical manufacturing, and analytical testing. Without proper filtration, even microscopic particles can throw off your results or damage sensitive equipment. It's like trying to drive a car with dirty oil—it just won’t work as well.

And let's not forget the health aspect. Some solvents, if contaminated, can be hazardous when inhaled or touched. Filtration helps mitigate these risks, keeping both people and processes safe. So yeah, solvent filters are kind of a big deal.

- Katmovies18com Your Ultimate Destination For Latest Movies And Entertainment

- Eva Longoria Elizabeth Judina Longoria A Journey Beyond The Spotlight

Types of Solvent Filters

Not all solvent filters are created equal. Depending on your needs, there are several types to choose from:

Membrane Filters

These are the workhorses of the filtration world. Membrane filters use a thin, porous layer to trap particles while allowing the solvent to pass through. They're super efficient and often used in labs for tasks like sterilization and particle removal.

Sintered Disc Filters

If you're dealing with larger volumes of solvent, sintered disc filters might be your go-to option. Made from materials like stainless steel or glass, these filters are durable and can handle rough conditions. Plus, they're reusable, which is always a plus for sustainability-minded folks.

Cartridge Filters

For high-flow applications, cartridge filters are the star of the show. These cylindrical filters fit snugly into filtration housings and are perfect for industries like food processing and water treatment. They offer excellent filtration efficiency without sacrificing flow rate.

Each type has its own strengths, so selecting the right one depends on factors like the solvent's viscosity, the size of particles you're dealing with, and your budget. But don't worry—we'll cover how to make that choice a little later.

Applications of Solvent Filters

Wherever solvents are used, solvent filters are likely nearby. Here are some of the most common applications:

- Pharmaceuticals: Ensuring drug purity and safety.

- Chemical Processing: Removing impurities from raw materials.

- Environmental Testing: Preparing samples for analysis.

- Food & Beverage: Filtering flavoring agents and other additives.

See what I mean? Solvent filters are everywhere, working behind the scenes to keep things running smoothly. And if you're in any of these industries, having the right filtration system can mean the difference between success and, well, not-so-success.

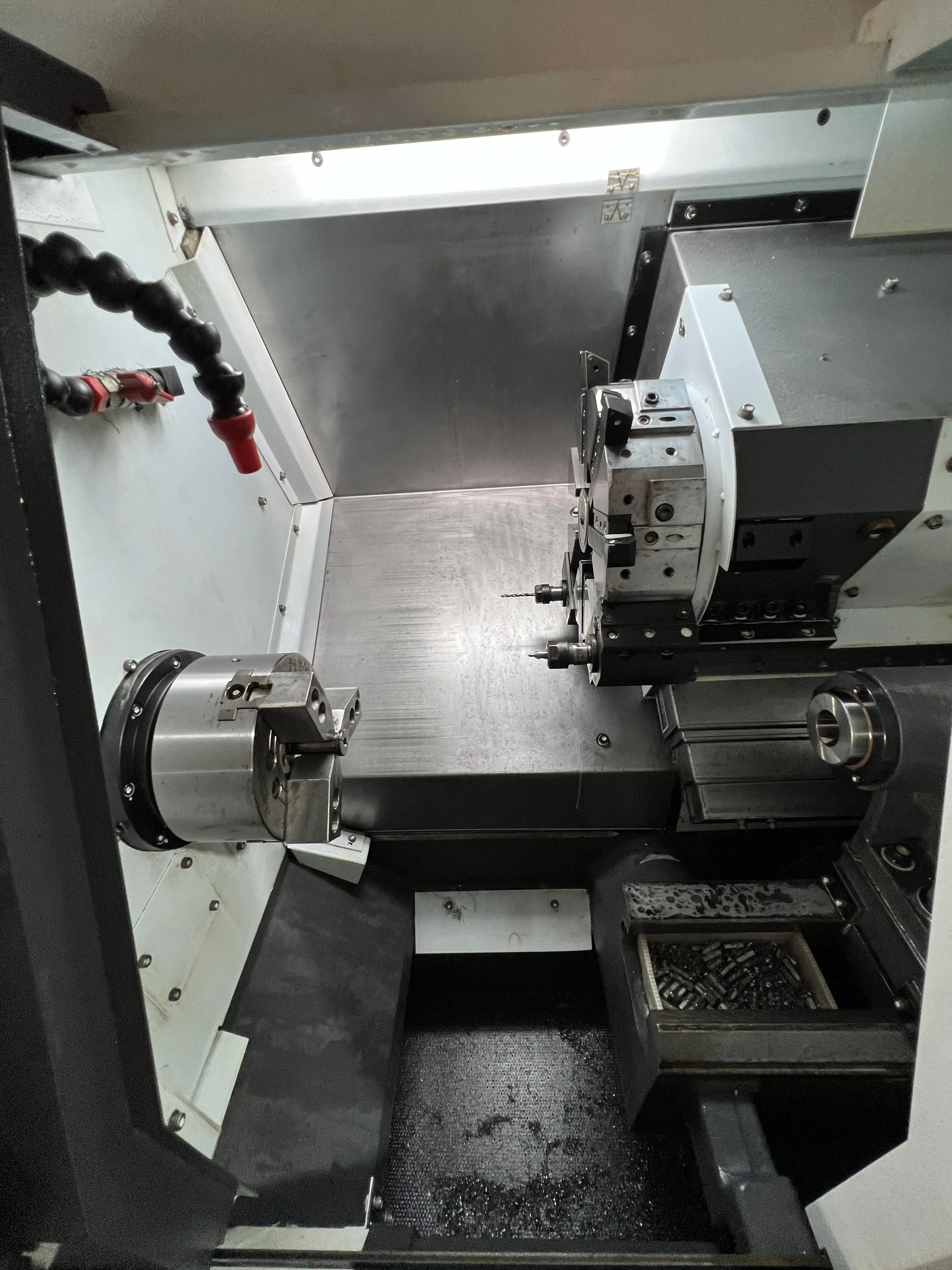

How Solvent Filters Work

Okay, let's get into the nitty-gritty. Solvent filters work by forcing the liquid through a medium with tiny pores. These pores are so small that they trap particles, bacteria, or other contaminants while allowing the solvent to flow through. It's like magic, but science-based magic.

Some filters use physical barriers, while others rely on chemical or electrostatic attraction to capture particles. The key is finding the right balance between filtration efficiency and flow rate. After all, no one wants to wait forever for their solvent to pass through, right?

Key Components of a Solvent Filter System

A typical solvent filter setup includes:

- Filter Housing: The container that holds the filter.

- Filter Medium: The actual material doing the filtering.

- Seals and Connections: Ensuring a leak-free operation.

Each component plays a vital role in the overall performance of the system. So, if you're building your own filtration setup, make sure everything is top-notch.

Choosing the Right Solvent Filter

With so many options available, picking the perfect solvent filter can feel overwhelming. But fear not! Here are some tips to guide you:

Consider the Solvent's Properties

Is your solvent acidic, basic, or neutral? Does it have a high viscosity or low? These factors will influence the type of filter material you should choose. For instance, polypropylene works well with many organic solvents, while PTFE is ideal for aggressive chemicals.

Think About Particle Size

What size particles are you trying to remove? Filters come with different pore sizes, ranging from microns to sub-microns. Make sure the pore size matches your filtration needs.

Don't Forget Flow Rate

How quickly do you need the solvent to pass through? Some filters are designed for high flow rates, while others prioritize fine filtration. Strike the right balance based on your application.

By answering these questions, you'll be well on your way to selecting the best solvent filter for your situation.

Benefits of Using Solvent Filters

Still not convinced? Here's why solvent filters are worth the investment:

- Improved Product Quality: Cleaner solvents lead to better results.

- Extended Equipment Lifespan: Fewer contaminants mean less wear and tear.

- Enhanced Safety: Reduced risk of exposure to harmful particles.

- Cost Savings: Prevents costly mistakes and rework.

It's a win-win-win situation. Who wouldn't want all of that?

Common Challenges in Solvent Filtration

Of course, nothing is perfect. Here are some challenges you might face when using solvent filters:

Clogging

Over time, filters can become clogged with particles, reducing their effectiveness. Regular maintenance and replacement can help prevent this issue.

Compatibility Issues

Not all solvents play nice with every filter material. Make sure you're using a compatible filter to avoid chemical reactions or degradation.

Cost

High-performance filters can come with a hefty price tag. However, investing in quality filters often pays off in the long run.

By being aware of these challenges, you can take proactive steps to minimize their impact on your operations.

Best Practices for Solvent Filtration

Want to get the most out of your solvent filters? Follow these best practices:

- Regularly inspect and clean your filtration system.

- Replace filters according to the manufacturer's recommendations.

- Train your team on proper filtration techniques.

- Keep detailed records of filter usage and performance.

These simple steps can significantly improve the efficiency and reliability of your filtration process. Plus, they help ensure compliance with industry standards and regulations.

Future Trends in Solvent Filtration

As technology advances, so does the world of solvent filtration. Here are some trends to watch out for:

Smart Filters

Imagine filters that can monitor their own performance and alert you when it's time for maintenance. Sounds cool, right? Smart filters equipped with sensors and IoT capabilities are already making waves in the industry.

Sustainable Materials

With growing concerns about environmental impact, manufacturers are developing eco-friendly filter materials. Look for options made from recycled or biodegradable materials.

Custom Solutions

One size doesn't fit all, and more companies are offering customized filtration solutions tailored to specific needs. From unique filter designs to specialized coatings, the possibilities are endless.

Exciting times lie ahead for solvent filtration enthusiasts!

Conclusion

So there you have it—everything you need to know about solvent filters. From understanding their types and applications to overcoming common challenges, this guide has got you covered. Remember, solvent filtration isn't just about removing impurities; it's about ensuring quality, safety, and efficiency in your processes.

Now it's your turn. Have you tried any of the tips or techniques mentioned here? Or maybe you have a favorite solvent filter brand you'd like to share? Drop a comment below and let's keep the conversation going. And hey, if you found this article helpful, don't forget to share it with your friends and colleagues. Together, we can make the world of filtration a little brighter!

Until next time, stay filtered and stay safe!

Table of Contents

- What Exactly is a Solvent Filter?

- Types of Solvent Filters

- Applications of Solvent Filters

- How Solvent Filters Work

- Choosing the Right Solvent Filter

- Benefits of Using Solvent Filters

- Common Challenges in Solvent Filtration

- Best Practices for Solvent Filtration

- Future Trends in Solvent Filtration

- Conclusion

- Adrian Paul Net Worth The Untold Story Behind The Legend

- Spice Up Your Life The Ultimate Guide To Sexy Videos Done Right

Solvent Filter N.B.Oler

Solvent Reservoir Filter/ Assy,Solvent Filter Equivalent To Waters Part

Solvent Reservoir Filter/ Assy,Solvent Filter Equivalent To Waters Part